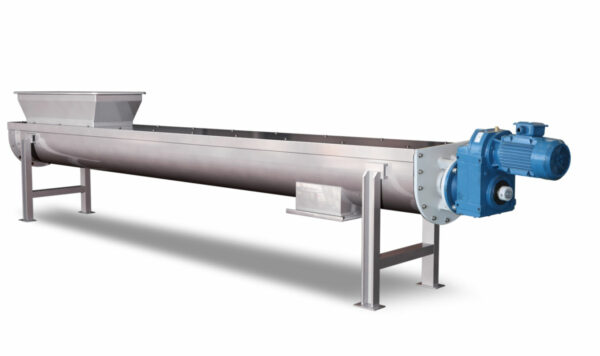

Screw conveyors can be customized to meet specific needs by considering a range of design factors.

Here are some ways that screw conveyors can be customized:

Size and capacity: The size and capacity of the screw conveyor can be customized to match the specific requirements of the application. Factors to consider include the desired flow rate, the size and shape of the material being transported, and the distance the material needs to be transported.

Screw flight design: The design of the screw flight can be customized to match the properties of the material being transported. Factors to consider include the material density, viscosity, and abrasiveness. Different flight designs can be used, such as ribbon, cut-and-fold, or paddle.

Material of construction: The material of construction can be customized to match the material being transported and any environmental or regulatory requirements. Common materials include carbon steel, stainless steel, and plastic.

Shaft seals: Shaft seals can be customized to prevent material leakage and contamination. Different types of shaft seals can be used, such as packing glands, mechanical seals, or air purge seals.

Hopper design: The hopper design can be customized to match the specific requirements of the application. Factors to consider include the material flow properties, the desired flow rate, and the available space.

Inlet and outlet design: The inlet and outlet design can be customized to match the specific requirements of the application. Factors to consider include the material flow properties, the desired flow rate,and the available space. Different inlet and outlet designs can be used, such as flanged, square, or round.

Motor and drive options: The motor and drive options can be customized to match the specific requirements of the application. Factors to consider include the power source, the available space, and the desired speed and torque.

Control options: The control options can be customized to match the specific requirements of the application. Different control options can be used, such as manual, automatic, or remote.

Ancillary equipment: Ancillary equipment, such as sensors, alarms, or automatic lubrication systems, can be customized to match the specific requirements of the application.

Overall, screw conveyors can be customized to match the specific needs of the application by considering a range of design factors. Screw Conveyor Play Important Role In Filter Plate Press Working with a qualified engineer or conveyor manufacturer can help ensure that the screw conveyor is properly designed and configured for the specific application.

Screw Conveyor Play Important Role In Filter Plate Press

Screw conveyors can play an important role in the operation of a filter press, particularly in the handling and transportation of the filter cake.

Here are some ways that screw conveyors can be used in conjunction with filter plate presses:

Cake discharge: Once the filtration process is complete, the filter cake needs to be discharged from the filter press. Screw conveyors can be used to transport the filter cake from the filter press to a storage container or disposal site.

Cake washing: In some applications, the filter cake may need to be washed to remove impurities or residual liquids. Screw conveyors can be used to transport the filter cake through a washing process, either as a batch or continuous process.

Cake drying: In some applications, the filter cake may need to be dried before it can be used or disposed of. Screw conveyors can be used to transport the filter cake through a drying process, either using heat or air.

Cake conditioning: In some applications, the filter cake may need to be conditioned with a chemical or other treatment. Screw conveyors can be used to transport the filter cake through the conditioning process to ensure that it is properly treated.

Cake storage: Screw conveyors can be used to transport the filter cake to a storage container or silo, where it can be held until it is ready to be used or disposed of.

Screw conveyors can offer several advantages when used in conjunction with filter plate presses. They can provide a continuous andreliable method of transporting the filter cake, which can improve efficiency and reduce labor costs. They can also be customized to meet the specific needs of the application, such as the required transport distance, the desired flow rate, and the material properties of the filter cake. Additionally, screw conveyors can be designed to handle a wide range of materials, including those that are abrasive, viscous, or prone to bridging or clogging.

However, it is important to ensure that the screw conveyor is properly designed and installed to ensure its proper functioning and to avoid damage to the filter press or the filter cake. The screw conveyor should be designed to match the size and capacity of the filter press, and the screw flight should be selected based on the specific properties of the filter cake. The screw conveyor should also be properly supported and aligned to avoid misalignment or damage to the equipment. Regular maintenance and cleaning of the screw conveyor are also important to ensure its proper functioning and to minimize the risk of contamination or damage to the filter cake.

In summary, screw conveyors can play an important role in the operation of a filter plate press, particularly in the handling and transportation of the filter cake. They can provide a continuous and reliable method of transporting the filter cake, and can be customized to meet the specific needs of the application. However, proper design, installation, and maintenance of the screw conveyor are important to ensure its proper functioning and to avoid damage to the equipment or the filter cake.